Charting the history and inner workings of Jaguar’s first premium diesel engine

Words: Paul Wager

Now that diesel is very much a dirty word, it’s ironic that Jaguar was criticised for being quite so late to the party when it came to oil burners. A cautious toe was dipped with the introduction of the X-Type diesel in 2003, its Mondeo-derived platform providing a useful development short cut, but the first all-Jaguar diesel model was the S-Type 2.7D introduced in 2004.

Developed in tandem with the Lincoln LS, the S-Type was one of those Jaguar products from the Ford era which clothed its high-tech underpinnings in a conservative retro-styled suit and in truth it was a state-of-the-art vehicle platform at the time of its launch.

Indeed, it was later repurposed for use under the original XF and an S-Type still feels remarkably solid today. All of which meant that a diesel version was naturally considered from the start.

Unlike the quick win available for the X-Type by borrowing the Mondeo’s four-cylinder Duratorq diesel engine, the bigger Jaguars needed something more refined and even in the larger global Ford network there was nothing suitable.

Rather usefully for Jaguar though, Land Rover was also in even more dire need of a suitably modern and refined diesel engine to suit its ever more ambitious climb upmarket. The upcoming Discovery 3 needed something more muscular than the old Td5 used in the Discovery 2 and for obvious reasons the BMW-sourced straight-six diesel in the Range Rover was commercially a non-starter.

The solution came in a joint venture between Ford and PSA which produced the engine codenamed Lion, but known in its Jaguar application as AJD-V6. Development had begun as early as 1998 and it was in fact the final stage of a three-phase agreement between the two car-making giants to produce a wide range of diesel powerplants for volume cars as well as the bigger unit for premium applications.

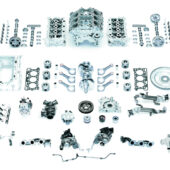

A clean-sheet design, the engine was developed for use in both transverse and longitudinal applications, the brief requiring the engine to be offered in a variety of different configurations and power outputs. The pinnacle of the line-up was to be the unit destined for Jaguar, with Coventry personnel seconded to the Ford project team from the beginning.

From the outset the engine was designed to be both lighter and more refined than the average diesel, something which started with the choice of material for the block itself. This was the first volume production engine block to be cast in Compacted Graphite iron (CGI) which uses shorter and thicker particles of graphite than the more common ‘grey’ cast iron used for car engines. The advantages of the material are lighter weight and greater strength – particularly important in a vee engine where the joint between banks creates a high stress load.

The greater strength of the CGI compared to conventional cast iron enabled the designers to use less material and consequently get the weight down to just 202kg – just 3kg more than the petrol V6 – although the press material of the time admitted that it had taken eight years to develop suitable machining equipment to handle the harder metal.

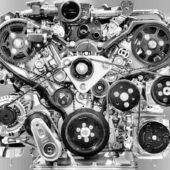

Topping off this advanced metallurgy was a pair of aluminium heads each boasting four valves per cylinder and twin camshafts as well as a port deactivation mechanism – a system also referred to as swirl flaps which opens and closes to promote swirl of the intake charge at lower engine speeds. The camshafts were belt driven in the name of refinement, with the press material of the time going to great lengths to explain the measures used to reduce noise in the assembly.

Belt-driven cams were used to improve refinement

The engine was a direct injection design but used a second generation implementation of the common rail injection system which increased the already high injection pressure to 1650 bar, with Piezo injectors employed to increase fuel metering accuracy. The ability to precisely control the fuelling in this way allowed the unit to run a low – by diesel standards – 17.3:1 compression ratio.

The engine would be offered in both single and twin-turbocharged versions, with the Jaguar units naturally being the twin-turbo unit, these being variable geometry units. Unlike older vacuum-controlled variable vane units, the AJD-V6 employed rotary electronic actuators which interfaced with the injection electronics to provide faster and more precise control.

In its final production form, headline figures were 204bhp at 4000rpm from the original 2720cc unit, backed up by the all-important 321lb.ft torque at just 1900rpm which was actually more pulling power than the 4.2-litre V8 could muster.

The V6 diesel first appeared in the S-Type in April 2004 when road testers were impressed by its blend of torque and refinement, one of them our very own Craig Cheetham writing in Auto Express. “The mid-range pull is incredible and high-speed refinement is up there with class leaders such as the BMW 530d,” reckoned Craig. “If you spend much time on the motorway, the new diesel’s relaxed cruising ability and incredible torque are preferable to a petrol model – and it returns 40mpg.”

Quite clearly that kind of economy added a whole new dimension to Jaguar ownership and when the unit was installed in the aluminium-bodied X350 XJ in 2005, the smooth and torquey diesel suited the car’s long-legged feel beautifully.

The 321lb.ft torque of the diesel is slightly ahead of the mighty 4.2-litre V8

Uprated to 3 litres in 2009, the V6 diesel would live on in the XF and the X351 XJ where it would in fact become the mainstay powerplant in terms of sales volume. The V6 diesel lived on in JLR products until the firm’s own Ingenium engines were ready in 2015, but in its decade-long production life the AJ diesel allowed Jaguar to leapfrog from catch-up to the front of the class in diesel power.