We explore the backstory of the AJ-V6, a mainstay Jaguar powerplant which was devised at Porsche and began life in a Ford

Words: Paul Wager

Mention Ford’s Duratec engine – the original V6, not the later confusingly renamed Mazda-derived four-pot – and you’re likely to hear two urban rumours. The first is that a penny-pinching Ford Motor Company created the Aston Martin V12 simply by welding two Duratec blocks together and the second is that the engine was a cast-off design picked up by Ford as a short-cut to creating a new V6 engine.

Neither is entirely true of course. An initial cutaway engine developed as a motor show concept display for the Aston V12 was indeed two Ford V6s hand-welded together, but the production engine used its own bespoke block, the bones of the rumour most likely stemming from the use of Duratec valvegear componentry.

The Porsche connection on the other hand does at least have an element of truth. Interviewed back in 1994 when the V6 engine was launched in the Contour (the US-market Mondeo), the appropriately named head of the V6 engine programme, Bruce Coventry explained that at the time Ford’s engine development resources were stretched so tightly that it turned to an outside engineering consultancy for assistance.

That third party was Porsche’s engineering services arm, which was responsible for the early development of the concept and explains why the unit shares certain features with Porsche’s own engines. Notably the design of the cylinder heads and the use of a main bearing ladder, both similar to the V8 engine used in the Porsche 928.

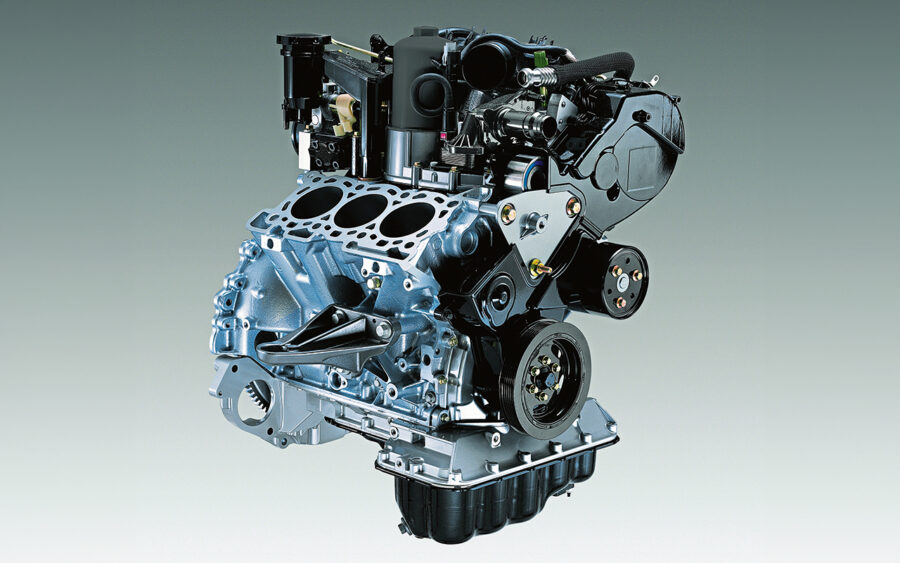

The brief issued by Ford was demanding: being intended for front-wheel drive transverse applications the engine needed to be sufficiently short to permit an 11-metre turning circle, while performance, emissions and economy naturally needed to be near the top of the class.

Compact size was a crucial element of the original design brief

Unsurprisingly for an engine developed in this era, the block was to be aluminium and was manufactured using a sand casting process licensed from Cosworth which rotated the unit during casting in order to improve uniformity of material quality.

A four-valve layout was envisaged from the outset, but low-end torque was a major requirement, Coventry explaining at the time that the team wanted to avoid the breathless feeling of so many mid-’90s V6 engines which had to be worked hard to access their power.

Accordingly, the Ford engineers looked to their other engines, taking inspiration from the variable intake system used on the 4.6-litre ‘modular’ V8 which used dual intake ports opening and closing as required to vary the effective inlet tract length.

The result was that in its early 2.5-litre form in the US-market Contour, the Duratec’s torque varied by no more than five per cent from 1500rpm right up to 5200rpm. “There won’t be a four-valve V6 that can match our torque curve,” boasted Coventry, who pointed out the significant torque advantage of the engine compared to Honda, Alfa and VW units at lower revs.

At higher speeds, the engine took on a different character as the inlet tract was effectively shortened and compared to Ford’s previous pushrod V6s, the engine was a free-revving paragon of refinement.

Clearly even back then a Jaguar application was in the plans and so NVH was also a major target, but another demanding part of the brief was reliability.

Features like a cam chain instead of a belt, a very efficient water pump and an over-capacity oil pump were clearly able to mitigate against the effects of neglected maintenance in later years and indeed the V6 engine in both Ford and Jaguar forms does have an excellent reputation for longevity.

An uprated Duratec first saw action in the limited production Ford Mondeo ST200. The first Jaguar AJ-V6 engine would soon follow in the S-Type in 2000.

As launched in its initial 2.5-litre guise, the Duratec was good for 170PS, but the later limited-production Mondeo ST200 (above) took that up to 205PS courtesy of a revised intake and exhaust, ported head, different cams and a larger throttle body from the 3.0-litre version already available by then in the USA.

In the go-faster Mondeo the character created by this old-school tuning work suited the car, but for an important new Jaguar production model a different approach was needed.

Accordingly, Jaguar’s own engineers proceeded to subtly modify the Duratec, using a revised cylinder head design which added a four-mode variable cam timing to the mix, as well as using direct acting mechanical bucket tappets.

The first of the Jaguar AJ-V6 versions to appear in production would in fact be the 3.0-litre version, using a 2967cc capacity achieved by using an 89mm bore on the same 79.5 mm stroke as the 2.5-litre unit – identical in capacity to the 3-litre option which had been used in US-market Ford products since 1996. This debuted as the Jaguar AJ30 in the S-Type in 2000 and produced 240PS at 6800rpm, with 221b.ft torque at 4100rpm. It would also later feature in the X350 generation of XJ.

The 2.5-litre version of the Jaguar engine, codenamed AJ25, would appear in 2002 powering the S-Type and was rated at 197PS at 6800rpm and 180lb.ft torque at 3000rpm. Created using an 81.6mm bore and 66.8mm stroke, a smaller AJ20 version of the engine was offered in the X-Type from 2002 and produced 159PS at 6800rpm with 148lb.ft at 4100rpm. Marketed as a 2-litre but at 2099cc technically a 2.1-litre, it was destined to remain a Jaguar-only variant of the Duratec family.

Powerful, refined and reliable, the engine proved entirely appropriate for its Jaguar applications and indeed would live on in Jaguar models after Ford’s European performance cars had abandoned the Duratec in favour of the Volvo-derived five-cylinder turbo. A refined version of the 3-litre would be offered in the XF from 2008, essentially the AJ30 but with the variable cam timing and intake control modified to be continuously variable in operation.

The original AJ-V6 would then live on until it was replaced by the AJ126 unit in 2012, derived from the Jaguar V8 and representing the severing of the last Ford engineering ties from the Jaguar line-up.