Over 30 years ago, BMW introduced its first V12 since the Second World War: the simple-yet-sophisticated M70 V12. Here’s all you need to know

Words: Andrew Everett

By the 1980s, BMW had already tried various V12 avenues – such as two M20 sixes joined on a common crankshaft – but it needed to think ahead. The M70 was being developed as the M20, with its iron block and adjustable tappets, was already teed up for replacement by its 24-valve M50 successor. BMW was also developing the all-new M40 engine to finally replace the M10 four-cylinder OHC unit that had been in production since 1962 – a well overdue replacement.

The M40 was smaller, lighter and quieter, as well more powerful and economical thanks to a piston crown and combustion chamber design that was very efficient. The M40 used finger rockers and hydraulic tappets plus it was also going to be produced in big numbers, so the M70 V12 was to be based on the M40 design and machined via the same tooling. BMW wanted to beat Mercedes Benz in building the first V12 passenger luxury car and this it so by four years.

However, BMW knew it wouldn’t be a big seller and as the 750iL was being launched in late 1987, the new generation of lightweight all-alloy, 32-valve V8 engines were already being developed, so the M70 was designed as a relatively low tech vanity project based heavily on high volume production parts. In fact, a number of its parts are from the M40, the connecting rods, valves and rocker arms are the same. The pistons are of a similar design but made from a different material and with slightly offset gudgeon pins, meaning the pistons are different from side to side.

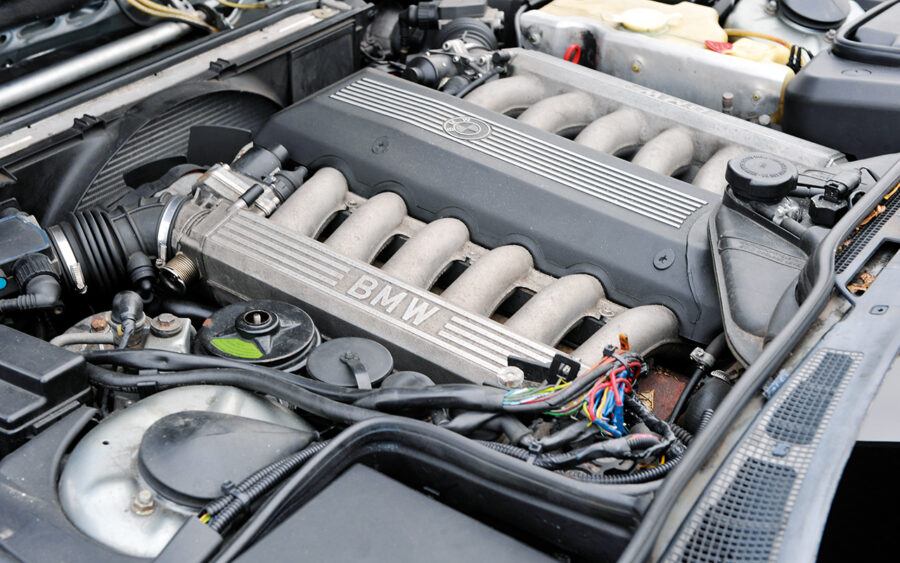

Unlike the iron block M40, the M70 used an alloy block with four bolt main bearing caps. The block was cast in Alusil silicon alloy where the cylinders are bored, honed and finished rather than steel sleeved. The honing process reveals tiny silicon crystals on which the special pistons and rings run. The steel crank was counterweighted and the cylinder heads bolted down with stretch bolts. The overhead cam on each bank fits into plain bearings, driven by a simplex roller chain from the crankshaft. The crank sprocket drives both the cam chain and a chain to drive the oil pump that is bolted to the underside of the block at the front. M40-type valves are operated by rocker fingers and hydraulic tappets, and the cams lubricated by an oil spray bar bolted to the camshaft caps and fed by pressurised oil. The oil filter housing is remotely mounted with reinforced rubber supply / return pipes whilst cooling is by a combined water pump and thermostat unit and a thermostat that opens at 85-degrees.

The electrical and engine management system was state of the art at the time, and the M70 V12 was the first BMW engine to use EML fly-by-wire throttles. Bosch Motronic 1.7 was used with two setups, one for each bank. This meant two sets of plug leads, distributor caps and crank sensors; the idea behind this was that if one bank went down, there was still 150hp on tap with which to limp home.

As launched in 1987, the M70 produced 300hp at 5200rpm with torque was rated at 332 lb ft at 4100rpm. This compared well with the Mercedes 560SEL, its 5547cc V8 producing 275hp and 317 lb ft of torque. The M70 bore and stroke of 84mm/75mm gave a cubic capacity of 4988cc with a compression ratio of a fairly low 8.8:1.

The 1987 BMW 750iL and the standard-wheelbase 750i launched shortly afterwards in 1988 were both limited to 155mph. BMW planned to increase the production of the M70 B50 dramatically with the 1990 E31 850i. For this very expensive new car, BMW offered a six-speed manual gearbox alternative to the 4HP24 automatic.

BMW M70 V12 known issues

The BMW V12 is a strong, unstressed and mechanically quite simple engine – no VANOS or multi-valve technology. It’s virtually unheard of to suffer head gasket failure or crankshaft bearing issues, and whilst camshaft wear can happen on the M70 and S70, it is rare. If you hear the ‘clack-clack-clack’ of a worn cam lobe, a new cam isn’t hard to fit once the timing chain has been detensioned.

Oil leaks are the big problem and the sump gasket can be an issue – and tough to fix. The M70 sump is a two layer alloy affair and it’s the sump to engine block gasket that will leak. The correct repair is to remove the gearbox to access the rear 10mm sump bolts but you can drill suitably sized holes into the gearbox bell housing to access them with a 10mm socket on a wobbly extension. BMW really didn’t think that one through.

Early 750iL cars were well known for EML problems, with the electronic throttle bodies being particularly troublesome, bringing on the EML light and going onto six cylinders. These problems were mainly sorted out by 1991 and the later M73 is generally very reliable with few problems. Water pumps can suffer sudden bearing failure and while it’s not too arduous a task on an M70 and S70, the M73’s bigger crank pulley damper has to come off before the pump can be replaced.

BMW M70 V12 applications

M70 5.0-litre

BMW 750i, 750iL (E32) (1987–1994)

BMW 850i, 850Ci (E31) (1987–1993)

S70 5.6-litre

BMW 850CSi (E31) (1992–1996)

M73 5.4-litre

BMW 850Ci (E31) (1994–1997)

BMW 750i/iL (E38) (1994–2001)