Jaguar is traditionally known for its straight-six and V12 engines but the AJ-V8 was arguably one of its best

Words: Paul Wager

When introduced in the XK8 and XKR sportsters of 1996, the AJ-V8 was only the fourth new powerplant in Jaguar history. Since Jaguar was under Ford ownership during this era, it’s often erroneously assumed that the engine was a Ford unit. And although that’s simply not the case, it is true that for some time the Jaguar design was used by Ford in the Lincoln LS and Thunderbird. The engine was first seen in a Jaguar under the bonnet of the X100-generation XK8 before gracing the engine bay of the X308 XJ and others.

Development work on the AJ-V8 began in the early 90s and the new engine was given the green light for production in 1993, with the finished product emerging just 36 months later. As ever with car engines, the brief was to deliver as much power as possible alongside the conflicting goals of low emissions, light weight and refinement. The weight was taken care of by using a die-cast aluminium block and sand-cast aluminium cylinder heads, while weight was further saved by using a proprietary low-friction nickel-silicone carbide plating called Nikasil for the bores and doing without cylinder liners – later abandoned.

The shape of the block casting incorporated a ribbed web cast high into the vee in order to link the two banks together in the interests of rigidity, while a closed-deck design further improved rigidity and provided a stable face for the head gasket. The two cylinder heads were ‘handed’ castings, each a mirror image of the other, and employed a four-valves-per-cylinder layout with a relatively narrow included angle of 28 degrees to provide a compact combustion chamber and a small cylinder head.

Extensive work had gone into the choice of combustion chamber design, with Jaguar even exploring the five-valve layout at one point, but the design chosen for the production engine was an evolution of the pent-roof four-valve design found in the AJ16. Providing an extremely high volume to surface area ratio, this helped optimise the thermal efficiency of the new engine. The valve gear itself employed relatively large valves with 35mm heads, but with a stem diameter of just 5mm, making them very light. With the cast iron camshafts drilled to save weight, this resulted in the reciprocating weight of the valve gear assembly coming in at just 3.05kg. The valves were operated by shimmed aluminium flat tappets using a single spring to reduce friction while spinning safely over 7000rpm.

A variable camshaft phasing system was employed using a hydraulic actuator fitted to each inlet camshaft, which was operated by electronically-controlled oil pressure valves activated by the engine management electronics. This system enabled the timing of the camshafts to be varied a total of 30 degrees from full advance to full retard in just 0.7 seconds, the end result being improved low-speed torque and high-speed power.

Drive to the camshafts was by a single-row chain – one primary and one secondary for each bank, both with hydraulic tensioners. The flat-topped aluminium pistons used a short skirt in the interests of reduced friction and the big-end journals of the con rods were fracture-split in the manner popularised by BMW. This process essentially involves splitting the parts in a precise way so that the two halves line up perfectly without the need for further balancing.

Running in five main bearings, the crankshaft was made from spheroidal graphite cast iron and extensive computer modelling was used to retain its stiffness in operation, alongside large 56mm diameter big end bearings. As was common by the late 90s, the inlet manifold was made from polyamide composite (plastic) for both weight saving and improved hot starting thanks to its superior insulation over a metal unit.

The whole lot was controlled by Jaguar’s own engine management system, produced by Nippondenso, which boasted two 16-bit processors and 192k memory – hefty computing power for the era. This was complemented by a drive-by-wire throttle which used a stepper motor to operate the throttle, although a mechanical back-up was provided.

Elsewhere, the cooling system was designed to warm up remarkably quickly. Called a ‘split block’ system by Jaguar, it used a ‘low volume, high velocity’ philosophy with the waterways designed to produce a fast coolant flow. It achieved a warm-up within four minutes in the urban test cycle, which enabled good fuel consumption figures as well as ensuring occupants were warmed by the heater sooner.

The end result was a 3996cc engine with a bore of 86mm and stroke of 86mm running a compression ratio of 10.75:1 to produce 290bhp, with an all-up weight of just 200 kg.

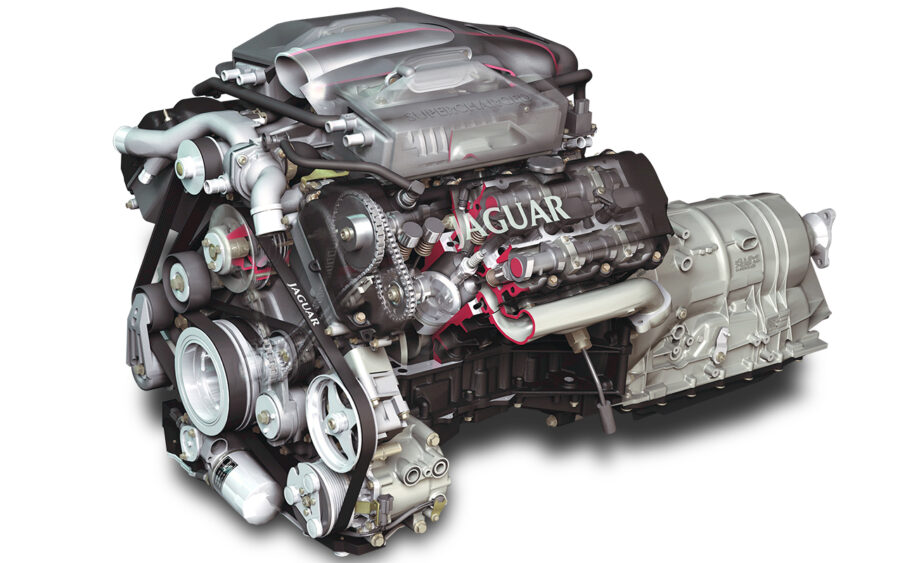

In 1998, the normally-aspirated V8 was joined by a ‘blown’ variant, using an Eaton M112 supercharger driven by belt from the front of the crankshaft with twin air-to-water ‘charge coolers’, one for each bank. First used in the XJR version of the X308-gen XJ saloon, the supercharged V8 was good for 370bhp at 6150rpm and a useful 387lb.ft. at just 3600rpm.

The more powerful 4.2-litre engine was introduced in 2002 for the 2003 model year and replaced the 4.0-litre unit, marking the first significant change from the original design with improvements to the block casting to further improve rigidity and refinement. The capacity increase retained the 86mm bore but used a 90.3mm stroke for a total of 4296cc – and rather impressively, the revised engine was even lighter than the original at just 194kg. Other revisions were mainly detail in their nature, including branched exhaust manifolds, new multi-hole fuel-injectors and further improved emissions systems. The variable cam phasing also gained more ability, now able to operate over a total of 48 degrees.

The supercharged variant now gained helical rotor gears to reduce noise and a coating on the rotors for improved efficiency, with the supercharger itself spinning 5% faster. The result was 300bhp for the normally-aspirated engine and a hefty 400bhp for the supercharged unit in the S-Type R.

In 4.4-litre form, the naturally aspirated AJV8 (codename AJ41) was found under the bonnet of Land Rover products including the Discovery 3, Range Rover Sport and full-size Range Rover. Jaguar’s V8 also made it into an Aston Martin, albeit in a thoroughly revised, dry-sumped and hand-built form as the AJ37. The unit was the sonorous powerplant for the 2005 Aston Martin V8 Vantage, with 380hp. Originally a 4.3-litre unit, it expanded to 4.7 litres in 2008 with an increase to 420hp.

Today, the AJ-V8 remains on sale in revised third-generation guise under the bonnet of various sporty JLR products, including the F-Type R, Range Rover Sport SVR and Land Rover Defender V8. The latest version includes variable valve and cam timing and a 5.0-litre displacement, along with a supercharger for outputs of over 500bhp in most applications.