Cheaper than the most sought-after examples but still a valuable classic, the E-Type Series 2 is a fantastic slice of iconic motoring history. Here’s how to buy one

Words: Rob Hawkins

There’s no denying that an E-type is expensive to buy and own, but some models are cheaper and offer better value for money. The E-type Series 2 is usually cheaper than an earlier Series 1 or 1.5, for example, but is powered by the 4.2-litre XK engine that’s easier to maintain than the V12 fitted to the later Series 3, offering a level of refinement that makes it a practical sports car.

The Series 2 is available in three models: the roadster or open two-seater (OTS), a fixed-head coupe (FHC) of the same external proportions and a longer 2+2 coupe. The overall length of these models ranges from 4.45m to 4.69m (14ft 7.25in to 15ft 4.75in), which is roughly the same as an early X-Type. They are, however, very slim at a mere 1.65m (5ft 5in) wide. They weigh a modest 1,197kg-1,422kg (heavier than a Mk2 Ford Cortina). The Series 2 is, arguably, more practical than its predecessors because the seating is more comfortable and the 2+2 offers more interior space.

The Series 2’s 4.2-litre XK engine should produce around 265bhp (at the flywheel), equating to an easily achievable sub-ten-second 0-60mph time without too much abuse. Fuel consumption should be around the mid-twenties to the gallon.

There are some tempting overseas E-type Series 2 examples, many of which are based in the US, but make sure you know what’s involved in importing such a vehicle and the costs incurred in transportation to and from the ports, import duties and the paperwork to register it in your home country. Consider also conversion costs, such as changing the headlights and switching the steering from left- to right-hand drive.

Emissions regulations may mean the compression ratio of the engine has been lowered and different carburettors fitted. American-market E-type Series 2 cars were equipped with a 3.54:1 final drive unit to cater for the lower speed limits and to help compete with big V8 muscle cars that could accelerate faster. However, these cars are also equipped with a limited-slip differential, which was dropped from home-market cars.

Abandoned imports may have expensive and collectible components missing, having been removed and sold separate to the car. Also, cars from the US are often run on a red-coloured antifreeze, which must be thoroughly flushed out to avoid any residue congealing with the recommended glycol antifreeze that’s usually coloured blue (although it is available in different colours to add confusion).

Bodywork

The E-type Series 2 sports bodywork consisting of a steel tub, doors, bonnet and bootlid or side-hinged tailgate. Being an early monocoque design, the rear subframe houses the differential, brakes and hubs, and it can be removed from the vehicle as a single assembly. At the front, there’s a framework made from Reynolds’ tubing that’s secured to the engine bulkhead. This framework supports the engine and front suspension. It cannot be weld-repaired, although new sections of tubing can be brazed into position. The framework doesn’t last forever, so it should be periodically replaced and costs around £3,000 (time intervals vary depending on the use of the car and the quality of the framework). Inspect it closely for corrosion, damage and cracks.

The steel body tub and panels are prone to corrosion, so inspect the wheelarches, sills, floors and door bottoms. Repair panels and replacement panels are largely available, but rarely cheap and often time-consuming to fit. For example, while a rear wheelarch repair panel costs around 100, should the inner section be corroded it can cost an additional £400, and that’s before you pay for welding and paintwork. Other panels and repair panels are similarly priced. An outer sill, for instance, costs around £140, whereas a door for an OTS can cost over £1,200 and a boot floor with rear valance (known as a rear-end assembly) costs nearly £1,500. Large and very expensive items include the bonnet, for around £10,000.

While the cost of panels can be expensive and, at times, difficult to decipher between good- and poor-quality items, what’s equally important is to ensure they are fitted correctly. When replacing the inner and outer sills, for instance, the body tub should be jigged to retain its shape.

Engine and transmission

If the engine runs, check the oil pressure after ten miles. It should be at least 45psi at 2,500rpm and 20psi at idle. If it is considerably lower, then the oil pressure relief valve may need cleaning or changing, or the engine may be worn.

One of the most problematic oil leaks on the XK engine in the E-type Series 2 is from the rear main oil seal as well as due to blocked breather pipes. As standard, it’s a rope seal (it originally contained asbestos), which is, in theory, perfectly adequate if the engine is routinely run to help prevent the seal from drying out and becoming brittle. Many owners live with oil drips that emerge from where the engine and gearbox are mated, but if you are paying top money for an E-type Series 2, it’s not so wise to accept the excuse that they all leak a little oil.

Should it need fixing, the engine and gearbox have to be removed and separated before the engine’s bottom end is stripped. When you are so far in at this stage, there is another option – upgrade to a modern neoprene lip seal, but that requires machining of the engine block and crankshaft, so you are halfway into an engine rebuild, which can easily cost upwards of £7,500.

Run the engine and listen for rattles and tapping from the top of the engine, which may suggest the valve clearances are incorrect or there’s a loose camshaft follower guide. The front of the engine where the timing chain, along with its tensioners and guides, are fitted and the bottom of the engine where the main and big-end bearings can wear, can become noisy.

Rattling tappets (incorrect valve clearances) are a time-consuming job, requiring the camshafts to be removed to extract the shimmed followers and change the shims. Rattles from the timing chain can often be remedied by adjusting the top tensioner. If the assembly needs changing, then it’s a time-consuming job, requiring removal of the cylinder head, sump and front timing cover.

Irrespective of the annual mileage and use, an E-type needs routine maintenance and checking over on an annual basis at the very least. Yearly engine oil changes are essential, even if the car hasn’t moved, because oil degrades, breaking down over time and absorbing moisture. So, it must be refreshed with the recommended 20W-50. Avoid recycled oil – check with the oil supplier or manufacturer before buying.

The engine coolant should be refreshed every two years, flushing the system and radiator. If not, a build-up of silt can block waterways and the water pump and potentially result in the engine overheating, leading to head gasket and engine failure.

The Series 2’s XK engine initially had short studs for the cylinder head, but Jaguar switched to long studs that extend into the coolant water jackets. If the coolant is neglected, corrosion of these studs is more likely, meaning a head gasket replacement job or an engine rebuild can result in the studs needing to be extracted and the remains drilled out if they shear. This is often an expensive and time-consuming job.

Brake fluid changes are often neglected, but must be done every couple of years. Being hygroscopic, brake fluid absorbs moisture, resulting in corrosion of components – such as pistons – inside the caliper and brake master cylinder.

Whether you buy from a dealer or private seller, ask for evidence of routine servicing, even if the car hasn’t seen much use. If a specialist has looked after the car, speak to them to find out what maintenance and repairs have been conducted.

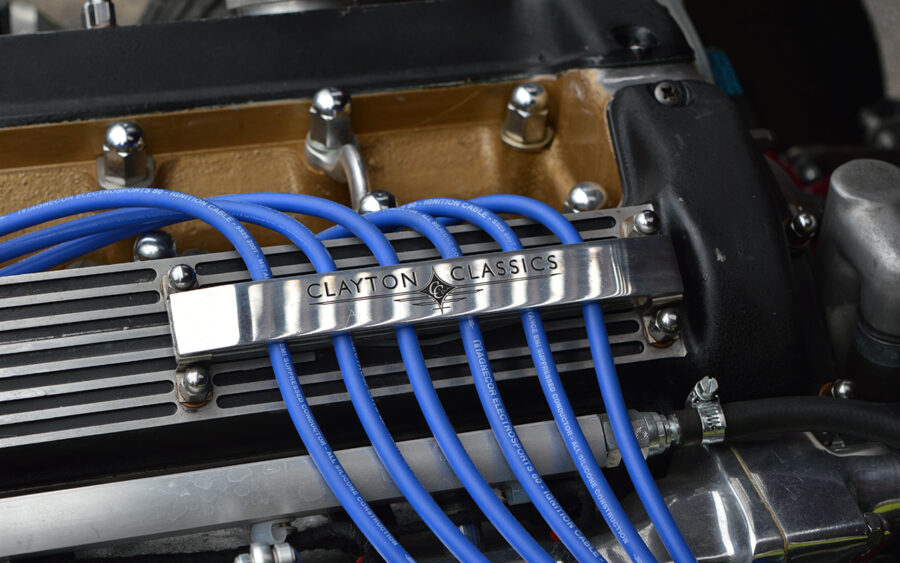

Some maintenance jobs are more complicated than expected. For example, the Series 2’s engine should be equipped with either two Zenith-Stromberg 175CD carburettors for export models or triple 2in SUs for the UK, and special tooling is required to set up and balance these carburettors. So, if you are looking at an E-type with a rough-running engine, don’t be persuaded that it simply needs a tune-up.

Borg-Warner’s Model 8 three-speed automatic gearbox was fitted throughout production of the 2+2, whereas Jaguar equipped the FHC and OTS with its own four-speed, all-synchro’ manual. Look for worn synchromesh on a manual (usually caused by the wrong oil, which should be EP90), jumping out of gear and erratic changes on an auto ’box, which are largely associated with general wear and tear. Budget for around £3,000 for the rebuild of an automatic gearbox and at least £1,000 for a manual. Clutch kits start at around £200.

Suspension, steering and brakes

The front suspension is mounted to the aforementioned Reynolds’ tubing framework and includes upper and lower wishbones with a separate telescopic damper and torsion bar, plus an anti-roll bar. The rear suspension is all secured to the rear subframe and includes lower wishbones, radius arms, coil springs and telescopic dampers, and each driveshaft is employed as an upper arm.

Worn suspension components can result in uneven tyre wear, annoying knocks and rattles and a poor ride quality. Rubber suspension bushes inevitably become worn and can often be replaced with longer-lasting polyurethane, although this can result in a harsher ride quality, so some owners prefer genuine bushes. Polyurethane can be beneficial, providing the Shore hardness is suitable.

Listen for clonks from the front during a test drive, which could be caused by worn dampers and anti-roll bar mounts. Similar rear-end clonks can be caused by worn radius arms. A visual inspection of the suspension can help to look for fractured and corroded coil springs and leaking dampers; ask the seller whether the suspension and drivetrain has been routinely greased once a year.

If you have the opportunity to raise a road wheel, try waggling the rear wheels from side-to-side. There should be a small amount of play in the wheel bearings; note that wear in the lower hub carrier pivot bearings is a common cause of rear wheel movement. Adjustment of the wheel bearing play is quite time-consuming because the shims need to be measured and changed, but it’s essential to have a little movement – if it’s too tight, the wheel bearing can overheat, damage can be done to surrounding components and, in the worst case, the end of the driveshaft can fall off, tucking the road wheel into the arch.

The E-type’s rack-and-pinion steering (power assistance was an optional extra) should feel light and positive with no sign of tracking or tramlining. Such problems may not be caused by the steering, but by the wrong choice of tyres, wheel alignment issues and worn suspension bushes or ball-joints. A reconditioned power steering rack costs around £430, whereas a non-power-assisted steering rack costs a little less, at around £400.

Brakes can be visually inspected and then checked during a test drive (if applicable). The braking system consists of servo-assisted, solid discs all round (11in diameter front, 10in rear), with some form of servo-assistance. Girling three-piston calipers are fitted to the front brakes. A lack of use and infrequent brake fluid changes can result in sticking pistons, but these calipers can be dismantled and repaired (repair kits cost around £30), or new and reconditioned calipers fitted, from around £100 each. The front brakes can be visually inspected by raising the bonnet. Look for corroded discs and brake pipes, and perished flexi-hoses.

The rear brakes are not so easy to inspect because they are inboard-mounted; a visual inspection is only possible from underneath. Testing whether the handbrake works is one way to find out if they have been serviced, although this is a separate mechanical system that operates against the same brake disc as the twin-piston caliper for the footbrake. If you have any doubts about the rear brakes (an MOT test will show whether they are working), don’t assume they will be quick and easy to fix. It may be easier to simply drop the rear subframe and overhaul everything attached to it.

Brakes that stick on might be caused by seized pistons inside the caliper, flexi-hoses that have broken down internally, or a neglected reaction valve. The latter is located on the brake master cylinder and should be routinely greased using rubber grease to ensure it remains free-moving.

The good news with the E-type’s braking system is that most components are available and affordable. A brake master cylinder, for instance, costs around £250. A repair kit for the brake servo costs roughly £60. And there are even preformed brake pipes for around £220 for a full kit.

Neglect of maintenance often leads to major repairs. If the handbrake doesn’t work, for example, the rear inboard discs and calipers may need to be stripped, which isn’t a five-minute job and could mean the rear subframe has to be removed.

Interior and trim

It’s highly likely that an E-type for sale is going to be dry-stored and rarely used in the rain, so it’s not so easy to check whether the interior is watertight. However, roadsters are rarely leak-free, so check the hood fits and the seals are supple and springy. Listen and feel for air leaks during a test drive (with the hood up); the same applies to other models.

Check the condition of the carpets and upholstery. Major expenses include a pair of front seat covers for around £850 (and the same for rear seat covers) and about £400 for a wool carpet set. The cost of replacing trim can soon add up. A pair of door panels with capings costs around £280, but, add another £110 or so for a pair of moulded-plastic armrests, £20 for clips and £30 for plastic inserts, and the final bill soon starts creeping up to £500. Our advice is that if an interior is missing or needs fully overhauling, budget for £2,000 or more (excluding instruments, steering wheel and dashboard).

Check all the instruments and switches work and the instruments are illuminated when the sidelights and headlights are switched on. Waggle the steering wheel up-and-down, from side-to-side and back-and-forth to check for play. There are no separate bushes to replace in the column; instead, there’s a sealed collapsible unit to replace, which, according to SNG Barratt, isn’t available anymore. It sells a bearing conversion kit for around £80, and strongly recommends that it should be professionally fitted (machining is required), and only to a column for a car that hasn’t been involved in an accident (if the column has collapsed, it should be replaced). Also, check the boot-release mechanism works as it can be difficult to fix if the cable has seized or broken.

Jaguar E-type Series 2: our verdict

We’re perhaps a little biased towards the E-type Series 2; it seems to tick all the boxes as one of the cheaper examples of the breed, with a good level of practicality and powered by the largest XK engine of them all. It ironed out many of the problems associated with the Series 1 and 1.5, and is before the era of competition with the likes of Ferrari and its V12 engine (hence why the Series 3 uses a V12).

Restoration projects are never going to be cheap in the long run, but are better if you need to spread costs, whereas buying a roadworthy example doesn’t necessarily guarantee a lifetime of trouble-free classic motoring because an E-type Series 2 needs to be maintained and pampered to preserve them. What is evident, though, is that owning what many people consider to be the world’s most iconic and beautiful sports car is something that everyone should do if they have the opportunity.