Though more purebred Porsche than its predecessor, the 944’s M44 normally aspirated inline-four owes much to the existence of the 924

Words: Shane O’Donoghue

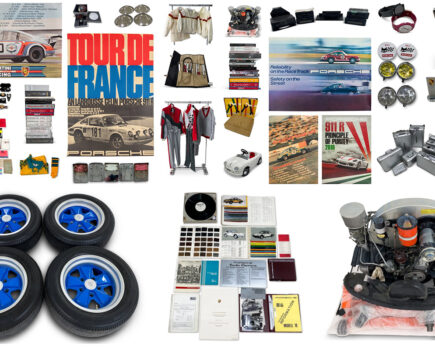

As the prices of all classic Porsches continue to rise, models previously snubbed by self-appointed connoisseurs are coming of age. As a case in point, the 924 has historically been regarded as the runt of the litter, despite its considerable commercial success; the later 944 was very much a ‘full fat’ Porsche product but we can’t tell its story without casting our minds back to the 924’s inception in 1970.

As a joint project between Volkswagen and Porsche to create an inexpensive mass-produced sports coupe which could be marketed under the different brands, Porsche took the technical lead on a car it expected to be a modern replacement for the boxy, Targa-topped 914. In a bid to keep costs down, however, Volkswagen stipulated an existing engine from its portfolio had to be used. The chosen powerplant, codenamed EA831, was earmarked to power the then new Audi 100.

Porsche took this engine and its accompanying manual gearbox as a starting point, though it moved the transmission to the back axle in order to evenly distribute weight and to give the 924 rear-wheel drive, thereby creating the successful ‘transaxle’ layout the Stuttgart concern’s front-engined, water-cooled, rear-wheel drive family of sports coupes would make use of until their discontinuation in the mid-1990s.

The engine’s bore and stroke were left untouched, measuring 86.5×84.4mm for a swept capacity of 1,984cc. It also suited Porsche that the EA831 inline-four was canted over by thirty degrees, which reduced the unit’s installed height, allowing the 924 to carry a low bonnet line. Nevertheless, Porsche favoured Bosch K-Jetronic fuel injection over the Audi’s carburettor.

Notably, Porsche was the first to use this advanced new system — known as Continuous Injection System (CIS) — which, really, was the bridge between fully mechanical fuel injection and later electronic systems. It launched on the 1973 911 T and, as the name suggests, there is continuous injection, not the pulsed high-pressure injection found on older systems. In fact, once the system is up to operational pressure, the injectors don’t open and close at all — they stay open and allow fuel into the inlet ports.

CIS also uses a complicated airflow sensor featuring a thin plate lifting higher the faster air flows through. The position of this plate is mechanically translated to what is known as a ‘control plunger’ in the attached fuel distributor, which then meters fuel to the injectors. The distributor also regulates the system pressure.

As you can see, this was a far more sophisticated setup than the Zenith carburettor used by Audi on the same base engine. Porsche also designed its own cylinder head, though kept the single overhead camshaft layout with a toothed belt drive.

The first Porsche 924 engine, launched in 1976, put out 123bhp at 5,800rpm, backed up by 122lb ft torque at 3,500rpm. Not startling numbers, even by the standards of the late 1970s, but the 924 was light, meaning it was pleasantly quick, rather than overtly powerful. Then, in 1978, Porsche launched the 924 Turbo, featuring a brand-new Porsche-designed cylinder head with a hemispherical combustion chamber and new spark plug position. A Kühne, Kopp und Kausch (KKK) turbocharger was fitted, with maximum boost set to a modest 0.7bar. Peak power rose to 168bhp at 5,500rpm with 181lb-ft torque at 3,500rpm.

An update in 1980 was designed to enhance reliability, though peak outputs also were modestly increased, resulting in 174bhp and 184lb-ft, due in part to the adoption of a Digital Ignition Timing Computer (DITC).

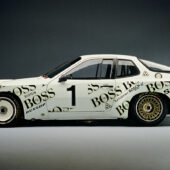

In turn, the 924 Turbo sired the 924 Carrera GT, conceived to homologate the model for racing. It added an intercooler, forged pistons and a larger turbocharger for an impressive 206bhp at 6,000rpm and 206lb ft torque at 3,500rpm. The race car, named 924 Carrera GTR, managed to extract up to 370bhp and 299lb ft from the Audi-based engine. This would be the end of the road for the punchy four-cylinder unit, but its development in the 924 taught Porsche a great deal, allowing the brand to be ready with a replacement engine before the world knew anything about it.

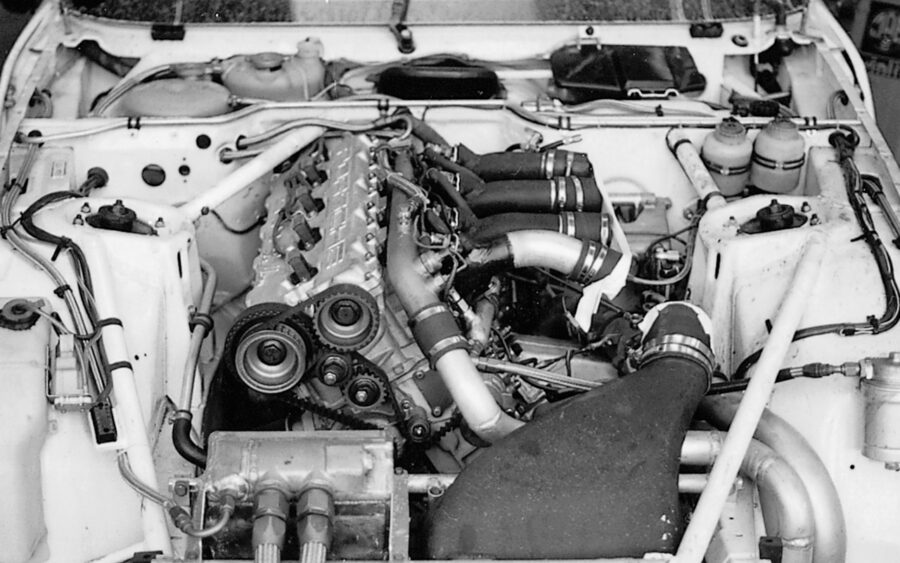

The new all-Porsche powerplant was first seen in the 924 Carrera GTP in 1981 (above), a motorsport machine entered in the GT prototype class at the 24 Hours of Le Mans that year and subsequently regularly referred to as the 944 GTP Le Mans. In fact, this racer’s engine was a mishmash of components, using the aluminium block of the forthcoming 944, including its balancer shafts, with a bespoke double overhead camshaft cylinder head and dry-sump lubrication, plus a KKK turbocharger.

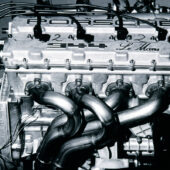

In hindsight, the design of the belt drive at the front of the engine clearly influenced Porsche’s later developments. From the nose of the crank, a timing belt drove a large-diameter exhaust camshaft pulley, but within this, and protruding from it, was another smaller toothed pulley. A short rubber belt drove the intake camshaft from the smaller pulley, with a neatly packaged tensioner in the middle.

Porsche began this project in secret with hopes of entering three GT cars and challenging for overall victory at Le Mans in 1981, helping give its yet-to-be-revealed 944 a serious start in life. However, while the special engine was seriously powerful — it topped 500bhp in initial testing — it could not deliver big performance reliably for the duration of an endurance race. There wasn’t time to develop the unit further, which is why Porsche instead reduced performance in the name of reliability, scaling back its ambitions for the race car by limiting the Le Mans entry to a single ‘prototype’. Nonetheless, it finished a creditable seventh overall behind some very serious race cars.

This was the first sighting of what we now recognise as the 944’s M44 inline-four, though it should be noted, the Le Mans engine didn’t use this designation and shared only some of its components with the production variant which followed. Even so, the showroom-ready 944 was unveiled at the Frankfurt Motor Show just a few months later and Porsche could loosely claim the new model had already been proven at Le Mans.

The 944 came to market in 1982. Commentary suggested the new 2.5-litre engine was, in effect, a single cylinder bank of the V8 engine fitted to the 928. Of course, this was somewhat wide of the mark. For starters, if the M44 was at the same angle as a bank of the 928’s engine, it would be canted over at forty-five degrees, which would require a much bigger engine bay. Instead, the M44 was angled at thirty degrees, just like the 924’s beating heart. That said, the M44 did share many of the 928 engine’s concepts and construction techniques, as we’ll now examine.

The 944’s engine had a 100mm bore and 78.9mm stroke, which were dimensions the 928’s V8 was originally designed to accommodate (for five-litre capacity) before its bore was reduced to 95mm. In 1980, the 928’s engine was eventually enlarged with a 97mm bore (and the five-litre V8 emerged in 1985), but even so, it was clear the M44 would have to make use of bespoke pistons. The cylinder head design was similar to that of the 928’s, however, with a single overhead camshaft concept and two valves per cylinder, driven by a timing belt from the crankshaft. The valves, valve springs, bucket-style tappets and valve guides were common between the engines, too. Due to the fact the 944 engine project started later than that of the 928, however, it made use of newer engineering techniques, certainly in terms of combustion chamber design, much to the benefit of overall operation.

Nevertheless, the M44 shared the 928 engine’s bore spacing. The block was made of the same aluminium-silicon alloy, too, which didn’t require separate liners, while there was a forged crankshaft and sintered steel connecting rods. The latter were the same length as those found in the 928, but of a different design, though the bearings were interchangeable between the cars. All this was quite exotic in the early 1980s, especially for a vehicle in the price segment the 944 was destined to compete in.

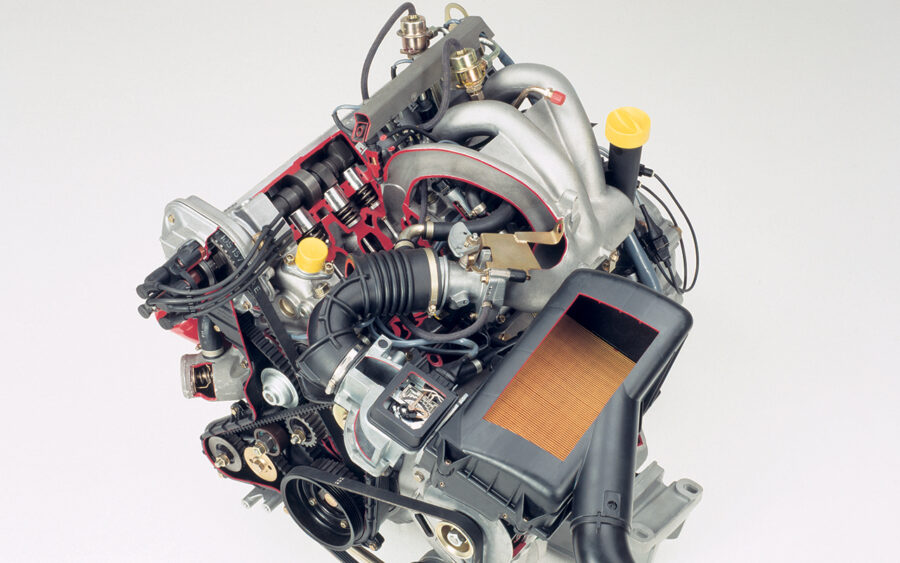

A key feature of the 944’s engine — not required in the 928’s V8 — was a balancer shaft system. This featured two counter-rotating shafts driven by a toothed belt from the crankshaft, turning at twice engine speed. The system was designed to smoothen out the inherent vibrations of a four-cylinder engine, a move Porsche deemed necessary when the 944 was going up against market rivals with six-cylinder units, as well as the rotary engine in Mazda’s RX-7. Not many people realise this, but after a period of research and its own in-house development work, Porsche decided to pay royalties to Mitsubishi in exchange for use of the Japanese manufacturer’s patented (and very good) design for the system, which is what you’ll find on the M44 production engine.

Each of the balancer shafts features two counterweights either side of the bearing the shaft runs in. One is mounted high up the engine block on the intake side, the other lower down on the exhaust side. To allow them to rotate in opposite directions, a rubber belt is toothed on both sides. Later in the M44’s development run, the balancing weights had to be altered to suit different piston weights.

The first iteration of the naturally aspirated M44 produced 161bhp at 5,800rpm and 151lb ft of torque at 3,000rpm. Useful increases over the 924’s numbers, we’re sure you’ll agree. In 1987, the 944 S was introduced, keeping the same 2.5-litre capacity, but with an advanced four valves per cylinder configuration, as well as a double overhead camshaft cylinder head, in line with what Porsche had developed for use in the 928 at the time. The timing belt run was changed moderately due to only turning a pulley on the exhaust camshaft, as per the 1981 Le Mans car. The intake camshaft was driven from the exhaust camshaft, but not by another toothed belt — it took its drive from a chain halfway along the length of the cylinder head.

A larger capacity oil sump and revised exhaust were also fitted, as was the latest Bosch engine control unit, complemented by a duo of knock sensors. The changes allowed Porsche to up compression ratio to 10.9:1 and quote maximum power of 188bhp at 6,000rpm, with 169lb ft of torque at 4,300rpm. Compare the engine speeds those peaks are produced at with the pre-S engine and you’ll get an appreciation for the newer unit’s different-revving nature. Indeed, Porsche altered gearing to suit this change.

In 1989, Porsche went a step further, increasing the M44’s bore and stroke to 104x88mm for a 2,990cc swept capacity. This resulted in the world’s largest four-cylinder production engine. As you’ll have read elsewhere in this magazine, it went into the 944 S2, producing 208bhp with a useful jump in torque up to 206lb ft. This version of the M44 featured the same compression ratio as the 944 S’s engine and also used a double overhead camshaft head design.

Although the 944 was replaced by the 968 in 1992, the M44 lived on, albeit with considerable further development, as is Porsche’s way. Indeed, the engine was a far cry from the modest Audi four-banger and, in the 968 (the final evolution of the front-engined, four-cylinder, rear-drive, water-cooled transaxle family of Porsche products and the last new front-engined Porsche prior to the arrival of the Cayenne in 2003), numerous mechanical upgrades would give the M44 a whole new lease of life.

The engine ended its tenure powering some of the most sought-after Porsche sports cars ever manufactured, including the legendary 968 Club Sport. A fitting last hurrah for this fantastic four.