The 917 was a racer like no other Porsche before it, with an exceptional engine at its heart developed in double-quick time. Here’s the development story of that engine – the Type 912 flat-12

Words: Shane O’Donoghue

The famous image above depicts 25 Porsche 917s parked outside the Porsche factory in Zuffenhausen on 22nd April 1969. The cars were readied for an inspection by officers of the Commission Sportive Internationale (CSI, then the independent competition arm of the FIA), who were sent to inspect and, ultimately, homologate the awe-inspiring racer that became a high point in the history of Porsche and its racing efforts.

The impressive line-up is fronted by 917-001, which first appeared at the Geneva Motor Show only a month earlier. Dressed in white with green detailing on the nose and rear wing, the car is marked by its factory model number. Even now, the image suggests Porsche had been planning the moment for years in readiness for total domination the sportscar racing world. Nothing could be further from the truth — the 917 was conceived less than a year before the picture was taken.

The project was a tremendous effort by all involved, but not helped by the CSI’s inspectors, who initially refused to homologate the car, not on technical grounds, but because Porsche simply hadn’t produced the required number of vehicles. Indeed, on the occasion of the CSI’s first visit to eyeball the 917, only three examples were finished. Eighteen more were in progress, though only seven sets of spares were available for scrutiny. Porsche made a strong argument for not building the full quota of twenty-five cars simply for inspection purposes, suggesting each finished build would need to be dismantled for race preparation thereafter — a costly and time-consuming process. The pitch fell on deaf ears, however, and the Stuttgart concern had no choice but to proceed with the assembly of all twenty-five units.

It mattered little that the finished inspection cars could barely drive a few metres — on their return visit to Werk 1, the CSI’s inspectors were suitably wowed and finally gave Porsche certification for the 917 to race. Interestingly, in an attempt to prove Porsche hadn’t cut corners, the company’s motorsport chief, Ferdinand Piëch, encouraged his esteemed visitors to drive any 917 they cared to select from the presented line-up. They declined his invitation.

Despite the extreme deadlines, Porsche didn’t compromise when it came to the 917’s engineering. Instead, the company raised eyebrows by investing a colossal sum of money into the project, commissioning the fabrication of parts in several different materials, just in case the lightest version wasn’t robust enough. Even so, robustness and reliability was baked into the 917 from the beginning, chiefly because the car was conceived to conquer the 24 Hours of Le Mans.

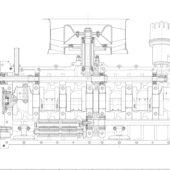

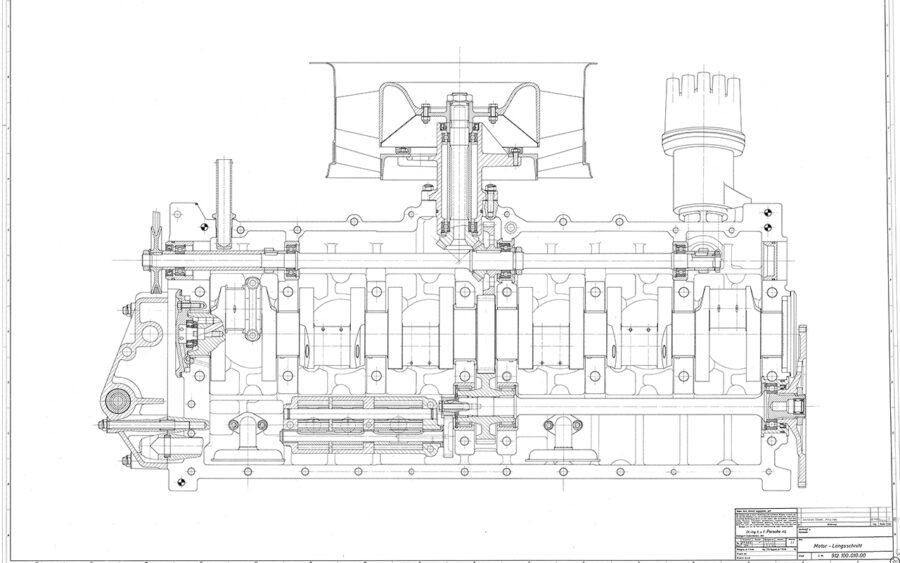

Diagram of the Type 912 engine’s longitudinal section, authored on 27th March 1969

With the spectacle in Sarthe in mind, plus the short period of time between drawing board conceptual designs and the finished car lining up on the grid, it seems mindboggling Porsche committed to the design of a brand-new engine in a new layout. Notwithstanding development of the Cisitalia Type 360 (a never-raced post-war Grand Prix car based on a Ferdinand Porsche design for Auto-Union in 1939), the company had never created a flat-twelve. And, because of the time constraints, Porsche didn’t have the luxury of producing a batch of prototype engines to evaluate and refine, as it would usually have done. Instead, the 917’s engine effectively jumped from sketch to production, though Porsche did manage to construct various test rigs to investigate sub-systems, such as those for cooling and fuel injection.

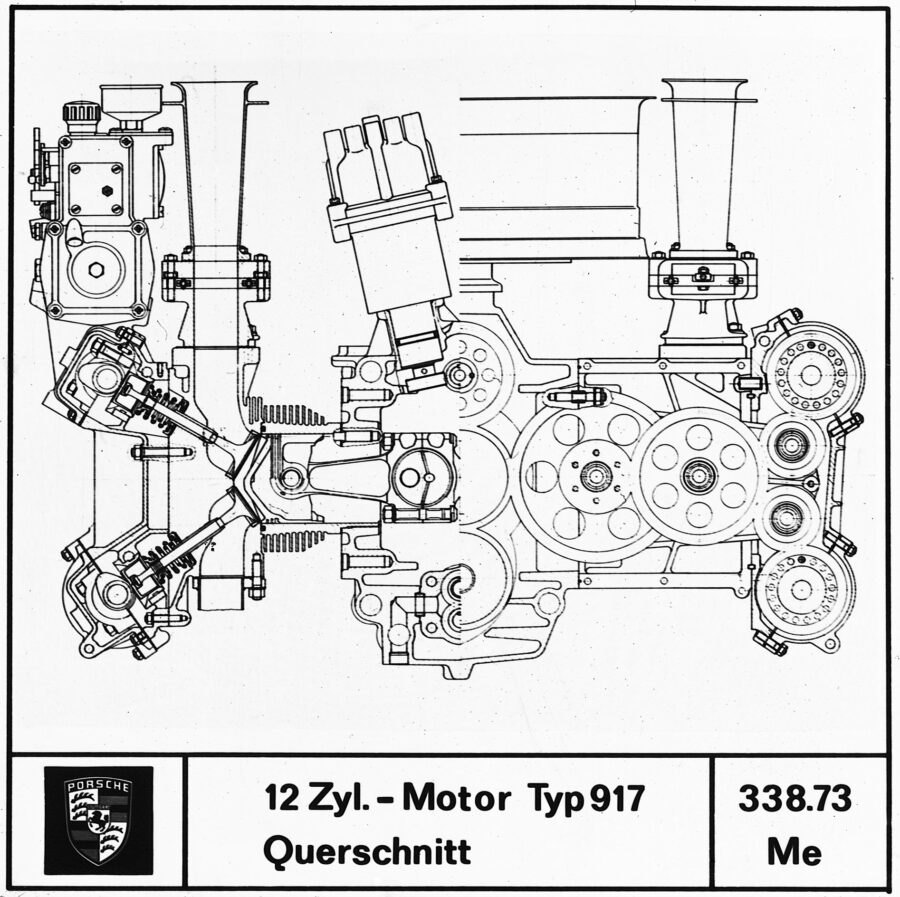

Perhaps opting for a flat-twelve wasn’t an idea as radical as it might first seem. Obviously, Porsche had vast experience with boxer fours, sixes and, in racing, flat-eights. The 917 needed considerably more power than all of these units were capable of delivering, however, which is why a twelve-cylinder powerplant seemed logical. Air-cooling was non-negotiable, given Porsche’s expertise and its use in all of the firm’s road cars up to that point. Besides, a horizontally opposed engine suits air cooling, and though it could mean a wider design, it would also result in a low centre of gravity.

The most time-critical component in development of the engine, and hence the whole project, was the crankshaft. Factory engineering genius, Hans Mezger, began work on this aspect of the build in 1968, as soon as the FIA announced rule changes allowing constructors to homologate a Group 4 racer for the International Championship of Makes with only twenty-five examples of the vehicle manufactured, as opposed to the usual requirement of fifty units. Porsche had not yet committed to creating the 917, but Mezger’s early decisions for its engine design may have been the catalyst for doing so — he chose to move the drive system to the middle of the crankshaft, instead of taking it from the end, as is the norm.

While not the first time this had been done, it was quite an unusual layout, albeit one bringing significant benefits. The primary reason for this design concerned torsional vibration of the crankshaft. To create the Type 908 flat-eight, Porsche had effectively added two cylinders to the Type 916 boxer-six, necessitating a longer crankshaft. It was beset with vibration issues, and it was predicted a flat-twelve crankshaft would be worse again, but while the ends of the long crankshaft would continue to vibrate in a twelve-cylinder application, the centre was relatively unaffected, meaning that the valvetrain wouldn’t be subject to such vibrations, much to the benefit of reliability.

The 917’s flat-twelve (confusingly codenamed Type 912, the name of the period’s entry-level Porsche road car) isn’t a traditional ‘boxer’ engine, where there’s considerable offset between opposing cylinders due to the carrying of the connecting rods on individual crank pins. In contrast, the 917’s beating heart features two connecting rods on each crank pin, as you’d find in a vee engine, which is why it could be thought of as a 180-degree V12.

Gerhard Küchle and Valentin Schäffer producing an engine for the 917 in 1969

There are some major advantages to this design, not least the reduction in the number of bearings needing lubrication. If each cylinder had its own crank pin, there would be a requirement for fourteen bearing journals, but with just six crank pins at play, there were just eight main bearing journals in the 917’s engine. This reduced the chances of lubrication issues causing failure, but it also lowered friction, while allowing for a shorter and lighter crankshaft. Obviously, the engine itself was shorter than it would have been without this design, too.

Despite the shorter crankshaft, Porsche was able to introduce wide connecting rod bearings and main bearing journals, again to the benefit of reliability. The engine also made use of titanium connecting rods, an approach Porsche had established on its earlier race engines. It took a while to perfect the construction of the new crankshaft, though. Initially, it was thought the drive gear in the middle of the crankshaft had to be of a different steel to that of the rest, primarily because the centre needed to be extra hard. Porsche looked at welding two ends of the crankshaft to the central drive gear. In the end, however, Mezger and his colleagues came up with a method allowing for the manufacturing of a single component with specific treatment for the centre section.

The resulting crankshaft sat in a two-piece cast magnesium crankcase held together with titanium bolts on its boundary and sixteen full-length bolts (two for each main bearing) responsible for the arduous work. The material for these bolts had to be carefully matched to the magnesium crankcase to reduce potential stresses caused by different metals expanding and contracting at different rates. The solution was a steel alloy marketed as Dilavar. Featuring up to six percent manganese and up to thirteen percent nickel, this special metal was used to produce the required bolts, which were paired with spherical washers to further relieve stress at elevated temperatures.

Driven by the chunky central gear drive was an output shaft underneath the crankshaft to the clutch at the back of the engine. Interestingly, in the name of longevity, the driven gear had one less tooth than that on the crankshaft, meaning the same teeth aren’t touching on every revolution. The downside to this is a slight reduction in torque to the transmission, but as we’ll see, the Type 912 engine wasn’t lacking in output. It’s worth noting the clutch pack diameter itself looks small given this powerplant’s output. The result of the tight packaging, the design required a completely new layout for the gearbox.

Above the crankshaft is another driven shaft, running the length of the engine. Internally, this turns the two distributors and the cooling fan sitting horizontally atop the engine. The shaft pokes out form the front of the engine to also turn the alternator. It might not sound it, but this is quite an elegant layout. Fiendishly clever, however, is the gear-driven valvetrain, using notably large diameter gears to bring drive from the centre of the crankshaft to the separate exhaust and inlet camshafts either side of the engine. During assembly of the 917’s flat-twelve, it was possible to adjust the camshaft timing due to how the central gears on the camshafts were held in place. The 917’s engine used two large valves per cylinder and also made use of twin-spark ignition for even more reliability. The valves were hollow and filled with sodium to help with heat transfer. Maximum inlet valve lift was 12.1 millimetres.

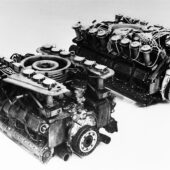

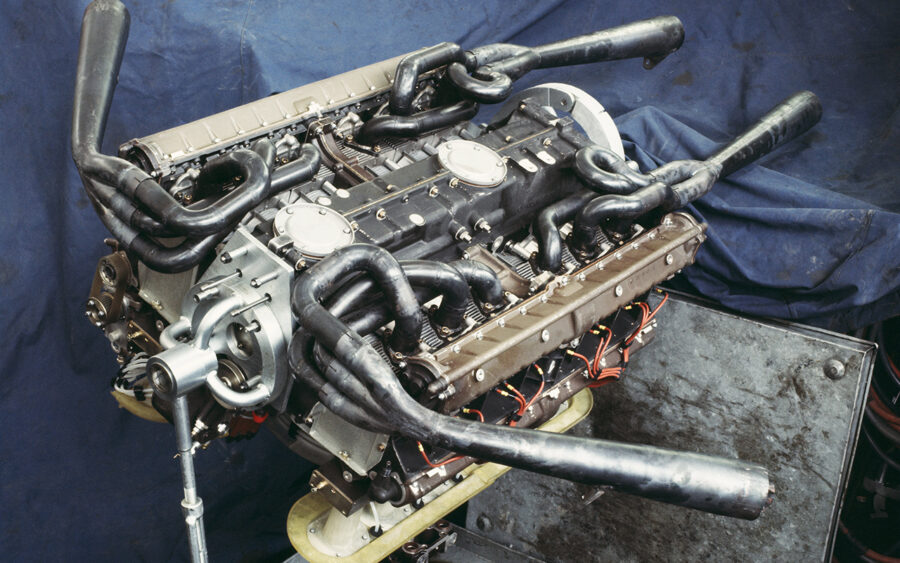

The 917’s fierce Type 912 racing engine, pictured in 1970

The individual cast aluminium cylinder heads were similar to those used in the Type 908 engine, though with shallower valve angles for a more compact combustion chamber. Initially, the Type 912 engine also shared the 908’s cylinder measurements, with an 85mm bore and 66mm stroke for a swept capacity of 4,494 cubic centimetres (4.5 litres). This was calculated to be sufficient enough to produce competitive power, with a safety margin within the five-litre class limit should Porsche feel the need to increase capacity further.

The outsides of the cylinders were finned for cooling and the bores were chrome-plated, with forged aluminium pistons within. These parts featured a domed top with valve cut-outs, two compression rings near their crown and an oil ring below the gudgeon pin. The bolts holding the cylinder heads to the crankcase were also made of Dilavar, but to allow them to warm up to the right temperature, they were shrouded from the cooling air provided by the main fan.

The latter, driven via a bevel-gear arrangement from the shaft above the crankshaft, was made of fibreglass, as was the jacketing to contain and control the movement of air over the engine. This can be seen in photos as a plastic-looking shroud exhibiting a semi-transparent amber finish. Not pretty, but certainly functional. It was efficient, too, the fan requiring less than twenty horsepower at peak engine speed. After all, a substantial portion of the engine cooling came from the oil.

A group of three gear oil pumps were neatly packaged into the crankcase, driven by the same shaft sending engine output to the clutch. One was a pressure pump and the other two were scavenge pumps for the crankcase. Another scavenge pump was turned by each exhaust camshaft. Using thermostatic control, when necessary, the hot oil was fed through an oil cooler mounted in the nose of the 917. Because the crankshaft had no drive system on either end, Porsche devised a method to deliver the oil for the big end bearings via the ends of the crankshaft. It was found to require much lower oil pressure than usual and was relatively independent of engine speed, much to the benefit of reliability. Oil jets to the undersides of the pistons were also integrated into the design.

At the top end of the engine, lower oil pressure was required, and lubricant was fed directly to the plain bearings of the camshafts, as well as to drillings uncovered when the bucket-style tappets descended two millimetres in their aluminium inserts. This technique, perfected by Porsche on earlier race engines, reduced the amount of oil flow required without compromising on dependable lubrication. Bosch came through with a new space-and-weight efficient fuel pump design, though as you can see in the pictures, it’s still a massive component sitting atop the engine, driven from the left-hand inlet camshaft via a toothed belt. Twelve plastic tubes delivered fuel to the plastic inlet trumpets, while slide throttles running on steel balls were employed to allow the air-fuel mixture into the intake ports — the slide throttle valves on both sides of the engine were joined by a solid linkage.

Ferdinand Piëch (right) together with Gerhard Mitter at the world premiere of the 917 at the Geneva Motor Show in 1969

In its first racing iteration, as used in the 1969 917 LH and KH bodies (long tail and short tail, respectively), the Type 912 engine produced up to 514bhp at 8,000rpm and 340lb-ft of torque at 6,800rpm. The compression ratio was 10.5:1 and top speed in excess of 210mph was recorded.

The design was quick straight out of the box, if not one hundred percent reliable. This is forgiveable given the timescales involved in design and production, but it only took to the end of the first season of racing for the 917’s flat-twelve to prove its worth.

The engine’s first race was at Spa in 1969, but retirement followed soon after the start. The well-established 908 won the event, continuing to be the favoured Porsche for twisty race circuits, while the 917 was proving fiendishly difficult to drive, even on relatively straight tracks. When the 917 could be tamed, it was undoubtedly fast, but by the time of the 1969 24 Hours of Le Mans, the car remained fiercely troublesome to control. This should hardly be surprising given the fact it effectively went from drawing board to production with little chance for refinement of design.

Teething issues with the flat-twelve were nothing when compared to the 917’s wayward handling. Even so, the 917s were quickest in the run up to Le Mans. Tragically, gentleman driver, John Woolfe, crashed his 917 on the first lap of the 1969 French enduro and died. Later, the leading 917 dropped out of the event with gearbox complaints just three hours from race end. The Type 912 engine, however, was relatively trouble-free. In the last race of the 1969 season, held at Zeltweg in Austria, just a matter of months after the 917 was cleared for homologation, Porsche engineering team’s expertise shone through when the now iconic sports prototype snatched its first victory. Signalling a big step forward in terms of reliability, both 917s entered into the race made it to the chequered flag, even if the drivers expressed concern about how challenging their new Porsche were to drive. Nevertheless, this race win set the stage for the following season, when Porsche took the decision to effectively outsource the actual racing side of its motorsport business in order to focus further development of the 917.

The Stuttgart squad contracted JW Automotive as the official works-supported team and development partner, an arrangement which brought with it the distinctive Gulf Oil livery we all know and love, as well as the considerable Le Mans expertise of team boss, John Wyer, a legend in the field of sports car racing and a man who had steered Aston Martin to success at Sarthe in 1959 and overseen Ford’s wins at Le Mans with GT40s in 1968 and 1969. Indeed, in advance of the 1970 season, Wyer and his crew were instrumental in discovering the 917’s handling issues were directly caused by a poor understanding of the car’s aerodynamics. This Eureka moment led to a significant redesign of the Porsche’s bodywork.

Porsche also used pre-season time to reinforce the flat-twelve in preparation for an onslaught on the 1970 World Sportscar Championship. The crankcase manufacturing technique was changed to eliminate cracking, while the bevel gear drive to the cooling fan atop the engine was altered to include a rubber coupling designed to absorb forces of sudden acceleration and deceleration. By way of reminder, this was driven from a shaft parallel to (and gear-driven from) the crankshaft.

Meanwhile, the exhaust system was completely redesigned. Originally, the Type 912 engine used four individual short exhaust manifolds and four outlets, one for each group of three cylinders. Viewed from under the engine, this resulted in two conventional-looking outlets pointing toward the back of the car and another two at an odd angle exiting ahead of the rear wheels. Unfortunately, the left-hand outlet (when viewing the car from the rear) sent heat into the pipes from the fuel pump to the injectors, which caused evaporation issues. Consequently, Porsche reconfigured the exhaust to create just two outlets pointing backwards. This required a considerable amount of re-routing to make all headers the same length, a desirable feature of a naturally aspirated engine, normalising back pressure in the exhaust ports.

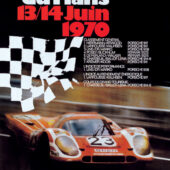

17 KH no.23, driven by Richard Attwood and Hans Herrmann to Porsche’s first overall victory at the 24 Hours of Le Mans

In Daytona, at the first race of the 1970 season, the 917 took a one-two, well ahead of the Porsche’s biggest challenger, the Ferrari 512 S. Enzo’s Prancing Horse won the next race at Sebring. This result perhaps doesn’t do the 917’s speed justice — the German machine suffered mechanical failure, but Porsche wasn’t about to rest on its laurels. As had been planned at the outset of the Type 912 engine’s design in 1968, Porsche quickly moved to increase capacity from the original 4.5-litres in a bid for more performance. A one-millimetre bore increase was paired with a new crankshaft (giving a 4.4mm longer stroke) to result in 4.9-litre swept capacity and power output close to 600bhp. More torque was delivered across the rev range.

This version of the flat-twelve debuted in one of the 917s competing at Monza in 1970 and set the lap record, but a puncture and crash put the car out of contention, allowing the Wyer team’s 4.5-litre 917 to take the win. Next up was Spa, where the 4.9 ran faultlessly — 917s finished in first, third, fifth and sixth places, interspersed by Ferraris. The scene was set for an enthralling Le Mans, which, as far as Porsche’s motorsport programme was concerned, was the Holy Grail. For many in the company’s racing department, other races were considered to be preparation for the event.

And prepared Porsche’s teams were, with no fewer than seven 917s on the start line. Ominously for all other competitors, Ferry Porsche had the honour of dropping the race-start flag at Sarthe, an honour in recognition of his company’s twentieth year of participation. As ever, the race was dramatic, and as has been well documented, Porsche emerged victorious, with 917s finishing in first and second place, followed by a 908 in third. Richard Attwood and Hans Herrmann took the top step of the podium following their winning drive in the red-and-white semi-factory car from Porsche Salzburg. This was Porsche’s first overall win at Le Mans. Job done.

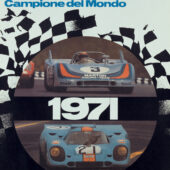

Unsurprisingly, Porsche also took the top prize in the 1970 International Championship for Makes, winning nine of ten races, seven conquered by the 917. The following year, the 917 again took seven victories, though wasn’t quite as dominant over the Alfa Romeo T33/3 as it was over Ferraris the year before. Not that Porsche stopped development of the 917, even with a forthcoming rule change for the 1972 season, outlawing big engines for the championship.

While the 917’s aerodynamics were the obvious focus of continued development, the Type 912 engine also received a significant upgrade in 1971. Its capacity was increased once more thanks to a modest bore widening, bringing the swept capacity up to 4,999cc. Peak power was up to 620bhp at 8,300rpm, with 433lb-ft torque at 6,500rpm. This increase in power was helped by a change in the bore treatment for the cylinders. Up to this point, the aluminium cylinders had chrome-plated bores, but the new five-litre unit was the first Porsche engine to use the Nikasil (Mahle’s brand name, an abbreviation of Nickel Silicon Carbide) treatment, allowing tighter manufacturing tolerances releasing more power.

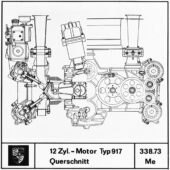

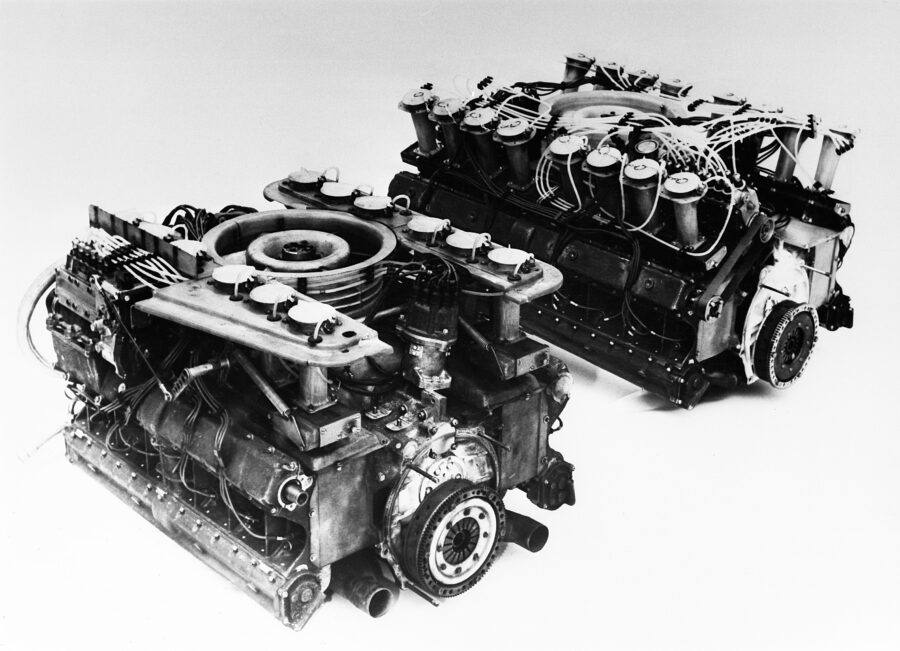

Porsche technical diagram of the 917’s flat-twelve for the 1973 season

The radical magnesium-framed Martini Racing 917 driven by Gijs van Lennep and Helmut Marko (now of Red Bull Formula One fame) won at Le Mans in 1971. With two victories at Sarthe and two world championships in its pocket, Porsche could proudly have retired the 917 at the end of the season. After all, there was the aforementioned significant rule change limiting engine size for the 1972 World Sportscar Championship to three litres, effectively outlawing the 917. Porsche, however, wasn’t done with the car. Well before its eligibility for the championship expired, the company’s motorsport department was plotting the next chapter in its star sports prototype’s career.

The focus of attention was Can-Am (short for Canadian-American Challenge Cup), a sports car series which began in 1966 with few technical restrictions, lots of prize money and, as the name suggests, large audiences in both Canada and the USA.

We need to jump back a few years in time to chart Porsche’s involvement with Can-Am. In 1969, the brand signed a deal with Volkswagen America to sell Audis alongside Porsches in the same North American showrooms. To publicise this partnership, it was decided Porsche-Audi branding would be used on a Can-Am racer. Subsequently, a special, open-topped, short-tail version of the 917 (labelled the 917 PA, the two letters representing Porsche and Audi) was hastily prepared for the second half of the 1969 season. Despite being driven by seasoned endurance racing driver, Jo Siffert, the car was comprehensively outclassed by the dominant McLarens.

Porsche created the 917/10 — a development of the 917 PA — for the 1971 Can-Am championship, but with the car’s naturally aspirated Type 912 engine, it too was no match for the might of McLaren. With a good new chassis in place, Porsche set about focusing on extracting more performance from the Type 912 engine. At first, a further increase in capacity was built, with a bore enlarged to 90mm and an unchanged stroke to create the 5.4-litre flat-twelve. Maximum power was therefore upped to 660bhp, but the McLaren cars produced more again. Siffert was the car’s lead driver, but couldn’t manage any better than fourth place in points positions.

After unsuccessfully experimenting with a sixteen-cylinder engine — weighing eighty kilograms more than the flat-twelve and requiring a chassis extension, which negatively impacted the 917’s already difficult handling — Porsche turned to turbocharging. Despite an early development of the technology being patented by Gottlieb Daimler in 1885 and American car manufacturers, such as Chevrolet and Oldsmobile, experimenting with snail-shaped bhp boosters in the 1950s and early 1960s, turbocharging in the automotive world was still in its infancy. Initially, Porsche didn’t know if a turbo could be successfully applied to the Type 912 engine without considerable redevelopment. Even a move to liquid cooling was considered. At first, a rudimentary twin-turbocharged system was tested, with pressure relief valves to control maximum boost, but it took quite some time before Porsche could get to grips with the power of the force-fed flat-twelve.

4.9-litre twelve-cylinder engine and five-litre sixteen-cylinder engine developed for the 917

The issues centred around drivability more than robustness. Porsche discovered the crankshaft, connecting rods and big-end bearings didn’t need to be altered to cope with the increased pressures. In contrast, detail changes, including a larger diameter output shaft and new flat-topped pistons, were required. The gearing to the cooling fan was also changed to increase its speed and hence the throughput of cooling air. Meanwhile, the path for airflow was simplified by way of less convoluted exhaust manifolds — the need for equal-length headers was eradicated by the addition of a turbocharger for each bank of cylinders.

In a bid to enhance drivability and response when off-boost, cam timing was made less aggressive and maximum inlet valve lift reduced. The valves themselves were made of titanium, hollowed out and filled with sodium to help with heat transfer. Various other detail changes to the exhaust valve operation were also made in an effort to deal with increased operating temperatures. As before, two spark plugs per cylinder were used and the same Bosch twelve-plunger fuel pump concept was employed, though with increased delivery capability.

Of course, the biggest changes to the Type 912 engine came on the air inlet side. The original naturally aspirated flat-twelve featured a dozen individual air trumpets open to atmosphere and using slide throttles. In place of these, the turbocharged engine featured individual throttle valves supplied with compressed air from a long tube manifold, one for each bank of the engine. These were joined at the front of the powerplant by a smaller tube, presumably to balance pressure. Running the length of the engine, these were joined to the compressor side of a turbocharger, again, one for each bank. Pressure relief valves were included in this piping, and it doesn’t take an engineering genius to look at images of the engine and realise there must have been a massive delay in response to throttle inputs at low speeds — the distance from the compressor wheel to the inlet ports is considerable.

Peak power, however, was no problem. Nearly 840bhp was achieved with the initial 4.5-litre capacity. As you can probably guess, power output was pretty much all or nothing. Moreover, this iteration of the Type 912 engine was a pig to drive at anything other than full throttle. Eventually, Porsche realised fuel delivery needed to be proportional to boost pressure, not just throttle position and engine speed, as had always been the case on naturally aspirated engines. This discovery led to changes to the fuel pump and a positive transformation for the driving experience. Turbo lag was still a major issue, though. Drivers had to predict when they’d want full power and push the accelerator pedal to the floor well ahead of time. This must have made for fraught laps on a twisty circuit.

Porsche worked hard to reduce the effect of this characteristic of the engine, adding a pressure relief system separate to the boost limiting valves on the piping to the tube manifolds. To keep the turbochargers spinning at unimpeded speed, the pressure relief system opened to atmosphere when the throttles were closed. Another feature to enhance response was a series of supplementary air inlets atop the tube manifolds, open when boost pressure was low, thereby admitting sufficient air to allow the engine to run better.

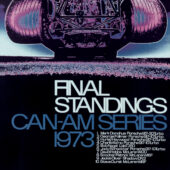

917/30 proved dominant in Cam-Am, leading McLaren — formerly the team to beat — to leave the competition and forcing organisers to change regulations

Buoyed by the performance and apparent robustness of the 4.5-litre turbocharged version of the Type 912 flat-twelve, Porsche tentatively applied the same approach to the larger five-litre engine. This not only increased power — to as much as 1,000bhp if the stories are true — but also helped with drivability at lower speeds and part-throttle situations thanks to the inherent higher torque output of the bigger capacity unit. This engine powered the new Penske Racing 917/10K in 1972. This was Porsche’s first proper attempt at taking victory at Can-Am, which it did by winning six of nine races. In fact, lead driver, George Follmer, won the drivers’ championship with more than double the number of points of his nearest competitor.

To maintain dominance for the 1973 season, Porsche created a turbocharged version of the 5.4-litre Type 912, which was rated at nearly 1,100bhp. It was reliable at that, but capable of much more. This fearsome flat-twelve was used in the stunning 917/30 Spyder, the most powerful sports car ever built and raced. In qualifying trim, the car was said to pump out as much as 1,600bhp.

Unsurprisingly, this 917 dominated the 1973 Can-Am season, winning six of the eight races, with Porsche drivers in the top four spots of the drivers’ championship come season end. Can-Am rules were quickly changed for 1974, limiting the amount of fuel which could be used in a race, a move clearly targeted at stopping the uncatchable 917s, which had forced McLaren to exit the competition. Perhaps unsurprisingly, the 917/30 was the last official variant of the now legendary 917.

In 1975, the 917 went out in style when Mark Donohue and Penske Racing brought a low-drag version of the 917/30 to the Talladega Superspeedway in Alabama, USA, to set a world record for the fastest lap on a closed course. AJ Foyt had managed 217mph the year before, but Donohue and the 917 clocked an average speed of 221.16mph around the venue’s high-banked oval, with top straight-line speed closing in on 240mph. Amazingly, this record was held for close to twelve years.

Aside from a brief and ill-fated return to active duty for the 917 at the hands of Kremer Racing in 1981 (when the team’s custom 917 K-81 qualified in the top ten at Le Mans, but retired after hitting a backmarker), and notwithstanding the Kremer car’s impressive performance leading the pack before suspension failure forced withdrawal at the year’s six-hour race at Brands Hatch at the end of the same season, the 917’s last official outing was the speed record attempt by Donohue, who tragically died in an accident during qualifying for the Austrian Grand Prix a week later. The 917 would live on, not least through the design of its many key components being carried over to other formidable Porsche racing machines, including the 936, which won at Le Mans in 1977. The engine powering this Martini-liveried racing machine? A 2.14-litre flat-six.

The Type 912 flat-twelve and its maker’s determined ongoing engine development programme paved the way for Porsche’s complete dominance of the sportscar racing scene and even influenced the Stuttgart brand’s biggest rivals, including Ferrari, which switched from a V12 to a flat-twelve for the Group 6 312 P in 1971. Later, Alfa Romeo and Mercedes-Benz also adopted flat-twelves for the World Sportscar Championship, though Ferrari went a step further by using the same design of engine in many of its production cars.

We might not see the likes of the Type 912 again, but the effect of this awesome powerplant and its influence in informing the direction of Porsche’s motorsport department can be felt all the way to the present day – and for that we should be very thankful.